Product life cycle management meaning – Product life cycle management (PLM) is a crucial concept that empowers organizations to manage the lifecycle of their products effectively, from inception to retirement. This comprehensive guide delves into the intricacies of PLM, exploring its stages, key components, benefits, challenges, and emerging trends.

Understanding the product life cycle management meaning is paramount for businesses seeking to optimize product development, enhance quality, reduce costs, and streamline operations. By gaining insights into the various stages of a product’s lifecycle, organizations can make informed decisions that drive innovation and competitive advantage.

Product Life Cycle Management Meaning

Product life cycle management (PLM) is a strategic approach to managing the entire lifecycle of a product, from its initial conception to its eventual end-of-life. It involves coordinating and integrating all aspects of product development, production, and support to optimize product quality, reduce costs, and streamline operations.

PLM plays a crucial role in helping organizations manage the complexities of product development and ensure that products meet customer needs throughout their lifecycle. It provides a comprehensive framework for managing product data, facilitating collaboration, and tracking changes, enabling organizations to make informed decisions and respond quickly to market demands.

Product life cycle management is the process of managing a product throughout its entire lifecycle, from development to disposal. It involves planning, organizing, and controlling the product’s development, production, marketing, and end-of-life processes. And investment in R&D is a pillar of decarbonization , as it helps to develop new technologies and processes that can reduce greenhouse gas emissions.

Product life cycle management can help businesses to reduce costs, improve efficiency, and increase customer satisfaction.

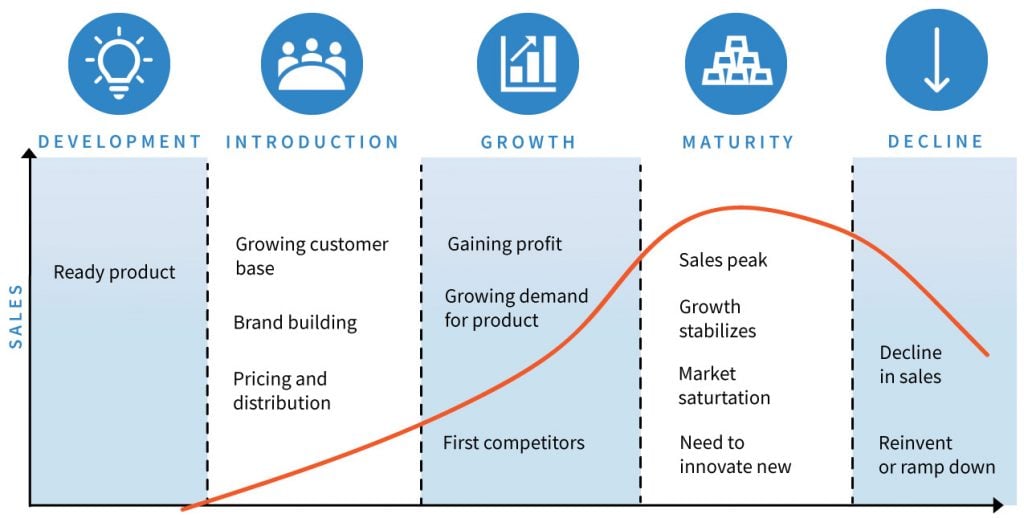

Stages of the Product Life Cycle

The product life cycle typically consists of four distinct stages:

- Introduction:The product is introduced to the market and sales begin to grow.

- Growth:Sales increase rapidly as the product gains market share.

- Maturity:Sales reach a peak and competition intensifies.

- Decline:Sales begin to decline as the product becomes outdated or replaced by newer technologies.

Examples of products in different stages of the life cycle include:

- Introduction:Virtual reality headsets

- Growth:Electric vehicles

- Maturity:Smartphones

- Decline:Desktop computers

Key Components of PLM

Effective PLM involves several essential components:

- Data management:Centralized storage and management of product data, including design specifications, manufacturing instructions, and marketing materials.

- Collaboration:Tools and processes to facilitate collaboration among cross-functional teams, including engineers, designers, and marketers.

- Change management:Processes for tracking and managing changes to product data, ensuring that all stakeholders are informed and that changes are implemented smoothly.

Benefits of PLM: Product Life Cycle Management Meaning

Implementing PLM systems offers numerous benefits:

- Improved product quality:Centralized data management and collaboration reduce errors and ensure that products meet specifications.

- Reduced costs:Streamlined processes and better collaboration lead to reduced production costs and faster time-to-market.

- Increased efficiency:Automation and integration of processes improve operational efficiency and reduce manual labor.

- Enhanced innovation:PLM facilitates knowledge sharing and collaboration, fostering innovation and new product development.

Challenges of PLM

Organizations may face challenges when implementing PLM:

- Data integration:Integrating data from disparate sources can be complex and time-consuming.

- Cultural resistance:Changing established processes and workflows can encounter resistance from employees.

- Lack of expertise:Implementing and managing PLM systems requires specialized knowledge and expertise.

- Cost:PLM systems can be expensive to purchase and maintain.

Case Studies

Successful PLM implementations have demonstrated tangible benefits:

- Boeing:Reduced development time for the 787 Dreamliner by 20% using PLM.

- General Motors:Saved $2 billion in annual costs by implementing a PLM system.

- Nike:Improved product quality and reduced design errors by 50% through PLM.

Emerging Trends in PLM

PLM is evolving to meet changing market demands:

- Digitalization:PLM systems are becoming increasingly digitalized, enabling remote collaboration and real-time data sharing.

- Artificial intelligence:AI is being used to automate tasks, improve data analysis, and predict product performance.

- Cloud computing:Cloud-based PLM systems provide flexibility, scalability, and cost savings.

Best Practices for PLM

Effective PLM implementation requires following best practices:

- Stakeholder involvement:Engage all stakeholders throughout the implementation process.

- Data governance:Establish clear policies and procedures for data management.

- Continuous improvement:Regularly review and improve PLM processes.

- Training and support:Provide comprehensive training and support to users.

Last Word

In conclusion, product life cycle management plays a pivotal role in the success of modern businesses. By embracing PLM principles and best practices, organizations can navigate the challenges of product development, deliver high-quality products, and stay ahead in a competitive marketplace.

The future of PLM holds exciting prospects, with advancements in digitalization, artificial intelligence, and cloud computing shaping the industry’s trajectory.

FAQ Section

What is the significance of product life cycle management?

PLM enables organizations to manage the entire lifecycle of their products, from concept to end-of-life, ensuring efficient and effective product development and management.

How does PLM improve product quality?

PLM provides a centralized platform for managing product data, change management, and collaboration, which helps to reduce errors, improve communication, and enhance overall product quality.

What are the common challenges in implementing PLM?

Organizations may face challenges in integrating PLM systems with existing infrastructure, managing data complexity, and gaining stakeholder buy-in. However, with proper planning and execution, these challenges can be overcome.